5 Ways Automated Packaging Can Save You Time and Money

The number of times a package is handled prior to getting into a consumer’s hands is skyrocketing. The more hands that touch a package, the more money that package costs the company. Packaging systems from decades ago, when manual labor was the only option, are limiting the growth of many warehouses today.

Automation can increase a warehouse’s productivity by generating more packages than one human laborer can per shift. This increase in throughput results in increased revenue for the company, but that’s not all automation can do to save time and money. There are several hidden costs of manual labor that every warehouse should consider when thinking about adding automation to their packaging process.

Increase Efficiency and Help You Get More Packages in the Hands of Your Customers in Less Time

Your company’s throughput has a direct impact on your bottom line. The key to increased throughput is efficiency. We have several options to help you increase automation in your warehouse, including helping you find the perfect conveyor for your product and more. When you increase automation, you have the ability to increase efficiency of your packaging process.

Once a box is perfectly erected, those empty boxes need to be filled with product, sealed and eventually packed on a pallet for shipping. The more efficient this process is, the more products you can get packaged and shipped to consumers. With our advanced Lantech technology, your cases can be queued to run on faster lines automatically, without minimal manual labor required.

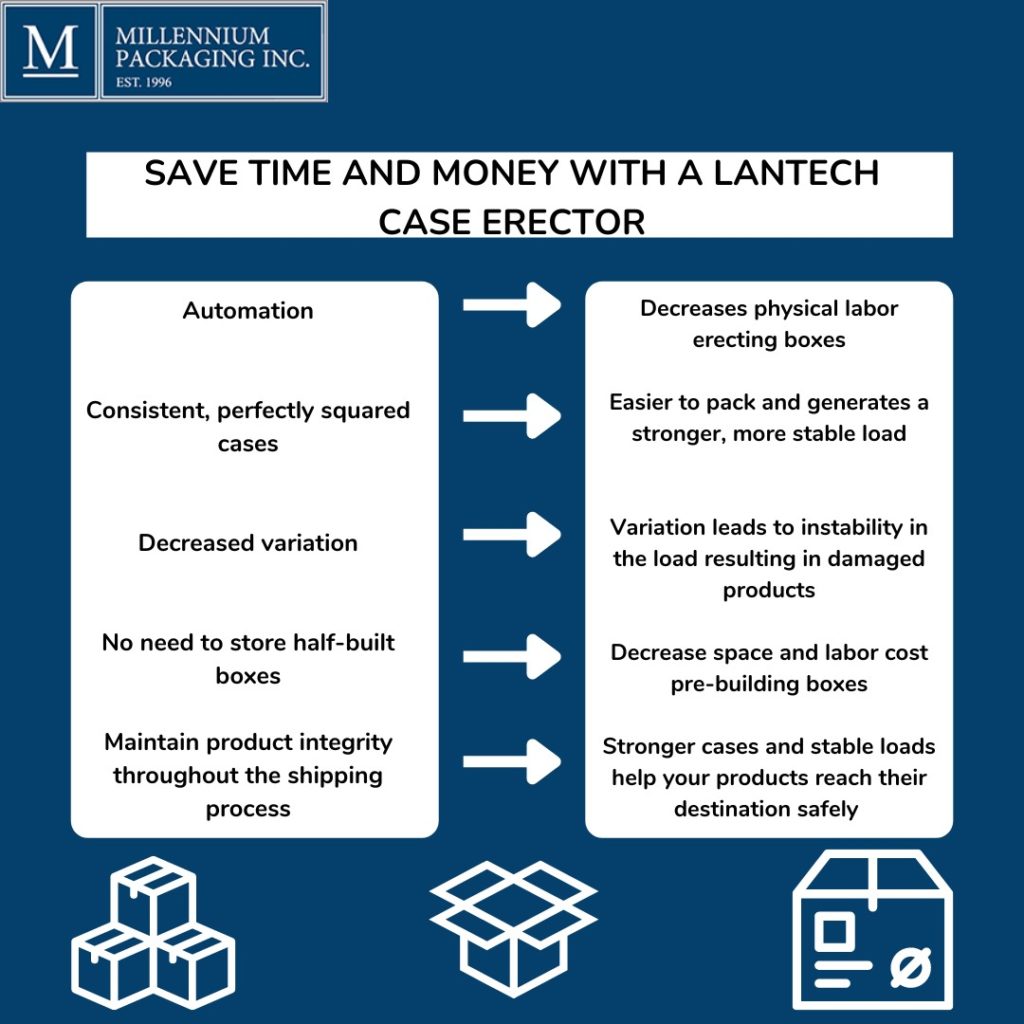

Decrease Damage to Products with Consistently Erected Cases Every Time

Manufacturing the perfect product to ship to consumers is the main focus of any company, but what happens when the product doesn’t arrive at the consumers doorstep in the same condition it left the warehouse in? Damaged products result when cases are not properly erected, stacked on the pallet correctly or secured in place with the proper stretch wrap.

The way a box is erected is key to protecting your loads and increasing throughput. A perfectly squared box will stack on a pallet easier and increase load stability, especially if that box is erected the same exact way each time. That is why our Lantech Case Erectors are so valuable. They not only increase the number of cases that can be erected, but ensure that each case is perfectly squared and in optimal condition to be stacked properly on your pallets.

The reality is that humans are imperfect and often generate high variability in their productivity. These variations can seem minor at first glance, but cost companies money in the long run. For example, when a box is erected by workers, each worker might have a slightly different method of erecting the same box creating variation from one box to another. These variations, however small they may be, can result in unstable loads that do not pack well. This instability can lead to damaged products.

Save money now with our automatic and semi-automatic Lantech Case Erectors. It’s the first step to ensure that your products are packaged properly to decrease damage and increase your productivity.

Minimize Time Spent Recruiting and Training New Employees

It’s no secret we have a supply and demand issue in just about every industry since the COVID19 pandemic. Many have blamed the labor shortage. It can be difficult to find warehouse workers, let alone experienced ones.

According to a Glassdoor Study, companies spend about $4000 to recruit and hire new, qualified employees. Once a company has hired an employee, even more money is spent to onboard and properly train these new employees. Combine this with the potential for decreased productivity as the trainer’s splits their focus between packaging products and training the new employee, the cost to the company for one new hire can add up quickly.

With automation, more productivity can be completed with less human capital, decreasing the need to recruit, hire and train new employees. Each warehouse could operate with less workers, further decreasing the cost for packing and shipping.

Adding automation to your packing process doesn’t have to be time consuming or difficult. When you purchase any of our Lantech automation equipment, such as our Lantech case erectors or stretch wrappers, our Lantech certified technicians will come out to your facility to help you set up your new equipment and train your existing employees.

Lower Overall Worker's Compensation Losses Per Year

According to the US Department of Labor, as of May 2022, there have been 6,927 new worker’s compensation claims filed in the state of Illinois alone. The total cost of these claims has totaled just under $250 million and we aren’t even half way through 2022 yet. It’s no secret worker’s compensation claims are costly, never mind the decrease in productivity because of an employee that is unable to do the full duties of their jobs.

Automation has the ability to decrease worker’s compensation claims in a number of different ways. The first, and most obvious way, is to decrease the need for more workers in the warehouse that could potentially be injured.

Another benefit to automation is that employees are not doing as many repetitive motions. For instance, sealing a case requires the employee to manipulate tape or box glue for each case that is packaged. This repetitive motion can cause overuse injuries as time goes on. With our Lantech Case Sealers, your employees no longer need to manually pull back tape or seal boxes, this is done automatically.

Our Lantech Stretch Wrappers decrease the need for employees to manually wrap pallets before they are shipped out of the warehouse. These machines not only handle wrapping the pallet with a click of a button, but some models are fully hands off meaning that employees do not need to leave the forklift in between pallets. Decreasing the strain on the employees joints, further minimizing the risk for injury.

When your warehouse has fully integrated automation in their packing process, your employees are now free to concentrate on more important things other than repetitive, mundane tasks. This not only frees up the employees time but decreases repetitive or careless tasks that could lead to injuries in the workplace.

Minimize Dead Storage Space in the Warehouse

Storage space is a huge challenge in many warehouses. Storing products to later be packaged and shipped is unavoidable so decreasing the need for storage in any way possible can help to increase productivity. When workers have to erect cases on their own, they often have to pre-build these cases to be stored and filled at a later date. Storing these cases takes up precious warehouse space that could be used for something else. Something that would directly increase the company’s revenue.

Stored cases are also subject to the elements of the warehouse. Temperature changes and moisture can damage cases. These damaged cases can cause variations if used to package products, increasing the risk for load instability and product loss in the shipping process.

Our Lantech Case Erectors are the perfect solution to free up space and protect your products in any warehouse. This machine allows for a quick and easy way to erect perfectly square cases in the fraction of a time it would take a human worker. Free up space and minimize losses in your warehouse and watch your productivity increase as a result.

Here at Millennium Packing, we understand the importance of running an end-to-end efficient packing process. From erecting the perfect case with our Lantech Case Erectors all the way to our Lantech Stretch Wrappers, we are here to support your needs. The ultimate goal is to get more packages out the door in less time.

We have several options to add automation to your packing process. Getting started can seem overwhelming, but our Lantech certified technicians are available to help. To learn more about Millennium Packing’s options for automation, contact our team of experts at (847) 719-6117.