The pandemic has not only changed the way consumers shop. It has also transformed the packaging and shipping industry. With shoppers turning to eCommerce options to purchase their essential and non-essential items, the shipping industry has played an indispensable role in the global response to the Covid-19 pandemic.

The shipping industry has gained immensely from the explosion of eCommerce. Just in the third quarter of 2020, UPS reported profits that were up over 11% compared to the same period in 2019. Shipping companies did their best to handle the rising demand and expanded capacity to handle the surge in deliveries during the pandemic. But with the gains, their shipping costs increased too. So, let’s take a closer look at the transformational effects that have shaken the shipping (and packaging) industry.

Shipping Is More Expensive

If the demand for delivery increases, so will the costs that are associated with the supply. But why exactly are shipping costs becoming pricier? There are certain factors that determine a package’s shipping cost.

• DIM Weight

Shipping has become more expensive since carriers introduced the Dimensional (DIM) Weight pricing. But what does this mean for shipping companies? Instead of only calculating the actual weight of the package, you have to consider how much space it will take up in a truck, or in other words, its cubic volume. For example, in June of 2019, USPS changed the Dimensional Weight divisor for packages over 1 cubic foot. The DIM adjusted from 194 to 166, which represented a 14% increase in volume cost.

• Shipping Destinations

For domestic shipments in the US, carriers use “shipping zones” that are based on zip codes to determine the distance a package travels from its origin to the final destination, and how much to charge. USPS decided to add DIM pricing to all shipping zones for Priority Mail, Parcel Select and Priority Express for all packages that are over 1 cubic foot.

• Type Of Package

The contents of your package matter. If you have to ship high-value, fragile, or temperature-sensitive products, you will require extra handling when packaging it.

Fierce Competition From Giants

Because of titans like Amazon Prime or Walmart.com, most customers now expect free and fast delivery, not understanding all that goes into delivering a package to their doorstep. With this competition, it is essential for mid-size retailers to keep up with increased demand for deliveries.

How do you keep up with the growing demand for delivery, while competing with colossi, with increasing shipping costs, and at the same time trying to keep costs at bay?

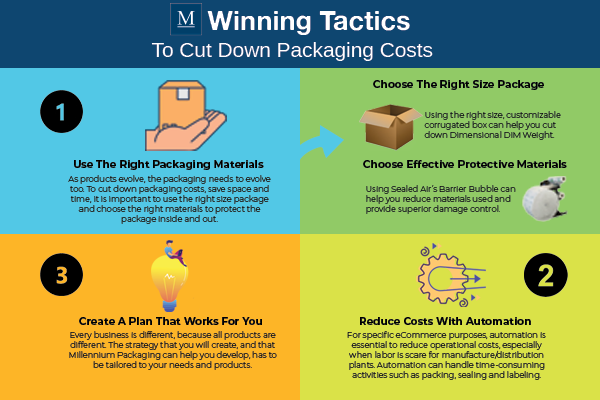

There is no easy answer, and there certainly isn’t an all-in-one answer that will solve everything. You can start from the bottom of the chain by looking at your packaging operations. Millennium Packaging is going to share some effective tactics that you can implement to cut down packaging costs and improve your bottom line.

1. Use The Right Packaging Materials

One common misstep is sticking to out-of-date packaging solutions. It is important for packaging manufacturers to take a step back and look at the requirements of the present. As products evolve, the packaging should and needs to evolve too.

Corrugated Boxes are one of the most commonly used packaging products. Optimized, fit-for-purpose packages offer better product protection in transit. Using the right size corrugated box can help you cut down Dimensional DIM Weight, thus reducing your shipping cost. Getting the right size for your packaging is simpler when using corrugated, because they are easy to customize. They are also a rather inexpensive packaging choice, and they are strong, yet lightweight. For a musical instrument distributor, Millennium Packaging customized their packaging so they could stack their product in a more space-efficient manner. The client was able to reduce their costs by 30% from their previous supplier.

If we shift our focus to inside the package, there are also ways to reduce packaging costs when using the right protective packaging materials. Moving from standard bubble to bubble on demand can help you save space, time, and dramatically reduce damage. Sealed Air’s inflatable cushioning materials are ideal in achieving superior damage protection, while reducing packaging costs. The NewAir I.B.® Flex™ by Sealed Air is able to produce custom shapes air cushioning packaging materials at speeds fast enough to keep up with demand. All inflatable materials include Sealed Air’s Barrier Bubble Technology that maximizes the inflation in every cell, reducing the amount of wrapping materials needed to provide superior damage control.

2. Reduce Packaging Costs With Automation

There is a common misconception that automation involves significant outlay, but that is not always the case. Understanding your packaging business and your objectives is what will help you recognize where automation is needed, since there is automation available for every stage of your packing process. But for specific eCommerce purposes, automation is essential to reduce operational costs especially when labor is scare for manufacturing and distribution plants. Automation can handle time-consuming activities such as packing, sealing, and labeling.

Whether you’re processing hundreds or thousands of orders each day, we realize the importance to have a reliable, effective, and accurate packaging system. Millennium Packaging provides solutions that offer flexibility to support the growth of eCommerce for a multitude of industries, including food and consumer packaged products, healthcare, and electronics. Millennium Packaging offers great options to automate your business. Our conveyors, infeeds, bagging machines, flow wrappers are built to delivery maximum efficiency. They all play an important role in warehouse automation, and they are designed to help you meet the growing demand in eCommerce fulfilment and distribution.

3. Create A Plan That Works For You

Shipping costs are increasing for all businesses in eCommerce, and it isn’t easy to determine the perfect eCommerce shipping strategy. Every business is different, because all products are different. The strategy that you will create, and that Millennium Packaging can help you develop, has to be tailored to your needs and products. But the combination of using the right materials and packing automation can certainly help you meet eCommerce rising demand while reducing packaging (and shipping) costs.

For more information on Millennium Packaging’s solutions please contact our team of experts at (847) 719-6117 or send us a message.